|

Foshan lesheng metal manufacturer

|

2020 hot sale !customized 600*600 aluminium ceiling metal stamping dies corner cutting edge bending mold

| Price: | 35000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

hydraulic press

full automatic

grid ceiling making machine

size:10/15/20

Clip in /lay on ceiling tile corner cutting and edge bending mold

company introduction:

After more than 30 years of research and development, Le Sheng metal products factory has a rich experience and professional design team. Aiming at the growing demand for products at home and abroad, our company has designed and developed a variety of automatic production lines and mold for metal building materials ceiling,like 300*300/600*600 sheet full automatic molding production line, the grille automatic production line and all kinds of sheet metal production line die equipment, etc., the company also produces various kinds of sheet metal parts for the customers.

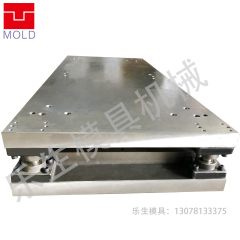

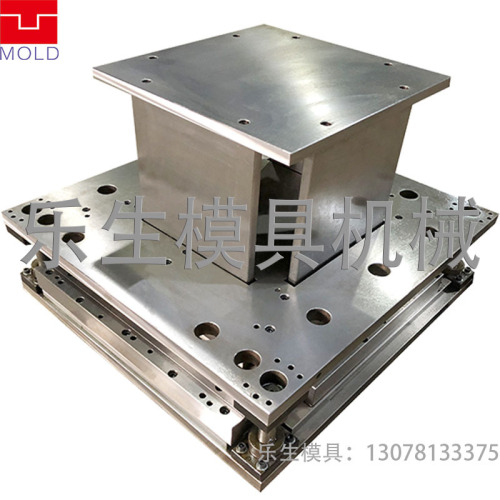

Below is our 600*600 progressive mold. Design by lesheng.

LESHENG Progressive MOLD SPECIFICATION:

Product Description

(1) Applicable to the wide area: hydraulic press machine & CNC machine,semi automatic or full automatic production line

(2) Making skill: Designed by our experienced engineer or depend on customer's specific design

(3) High quality steel material to make: Imported SKD11,D2,DC53 or customized

(4) Final product: Metal cutting,Metal bending,Metal forming,Metal perforation.

(5) Mould life time: 8,000,000 punchings.

(6) delivery time: 60days.

Mold parameter:

Mold manufacturer | Foshan Lesheng Metal manufacturer |

Brand | LESHENG |

Mold type | continous mold ,combination die |

ceiling size | 600mm*600mm |

Mold material | DC53,D2,A3,SKD11 |

Design Software | Auto CAD, PRO/E, Solid works, UG(NX), Cimatron |

Hardness | upon request |

Mould Size | Customized size |

Surface Tratement | Plating, Anodized, Electrophoresis, Powder Coating, Painting, Polishing. |

Mould Life | 8000000 shots ,deepends on the steel material and your customized |

Shipping and packaging:

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

Company detail introduction:

Foshan Nanhai District Le Sheng metal products factory was established in 1999. It is located in Nanhai District, Foshan, Guangdong province. It is adjacent to the South Yuen area. It is also located near the FoShan 1 ring road . The traffic is very convenient, the company has a workshop area of 5000 square meters. LeSheng company is a professional R&D,all kinds of cold stamping die, we have a professional design team and High precision advanced processing equipment,strong production technology and quality assurance.

All kinds of hardware moulds produced by our factory are trusted and recognized at home and abroad by high quality and complete after-sale service. The mould is sold well and sold to more than 20 countries such as Europe and America.

"Quality based, Customer first". Le Sheng is sincerely willing to move forward with you and Warmly welcome to our factory.

Hot search question about mold:

What is a progressive die?

Progressive die stamping is a metal forming process widely used to produce parts for various industries, such as automotive, electronics and appliances. Progressive diestamping consists of several individual work stations, each of which performs one or more different operations on the part.

What is die cutting used for?

Die cutting is the general process of using a die to shear webs of low-strength materials, such as rubber, fiber, foil, cloth, paper, corrugated fiberboard, chipboard, paperboard, plastics, pressure-sensitive adhesive tapes, foam, and sheet metal.

Can you die cut without a machine?

The truth is you are able to use die cuts without a machine and the aid of any difficult mechanics.

What is a stamping die?

A stamping die is a special, one-of-a-kind precision tool that cuts and forms sheet metal into a desired shape or profile. The die's cutting and forming sections typically are made from special types of hardenable steel called tool steel.

FAQ:

1.Q: Why choose us ?

We has many years of experience. Our products are sold well in home and exported to more than 20 countries and regions such as Europe and America.

2.Q:What should provide if I want to customized machine?

You need provide profile drawing, material, thickness, voltage and your special requirements.

3.Q:How is the product quality?

Our products are manufactured strictly according to national and international standard, and we take a test on every grinder before delivery.

4.Q:How to pay?

A. We usually accept T/T, L/C,D/P,Western Union,MoneyGram;

B. T/T: 50% in advance as down payment, the balance before delivery;

C. We take pictures of finished products before delivery.